And you thought you knew Parmesan.

Heading further north in our CHS Inc. sponsored agricultural immersion trip, the team’s next stop is the heart of Parma’s iconic cheese production region. Our team gathered at the Parmigiano-Reggiano packaging facility and donned our paper hairnets, overcoats, and plastic booties to enter the processing plant.

Guest blogger: Annicka Webster, MBA’15

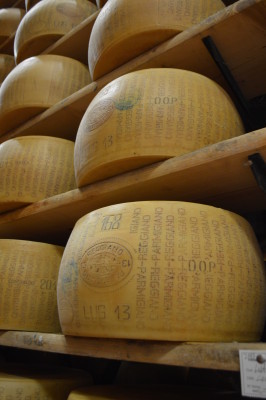

The tour began in the most hallowed of places: the parmesan storage warehouse. Here, artisan-crafted wheels of parmesan (400,000 in total) are aged for 24-30 months to develop the right taste and consistency of one of Italy’s most well-known cheeses. Like many of the traditional products made in Italy, the production and quality assurance of protected designation of origin (PDO) products like Parmigiana-Reggiano is overseen by a consortium. The consortium is responsible for protecting the designation of origin and preserves the cheese’s authenticity and rich history of production by guaranteeing the process followed by the area’s independent producers.

The tour began in the most hallowed of places: the parmesan storage warehouse. Here, artisan-crafted wheels of parmesan (400,000 in total) are aged for 24-30 months to develop the right taste and consistency of one of Italy’s most well-known cheeses. Like many of the traditional products made in Italy, the production and quality assurance of protected designation of origin (PDO) products like Parmigiana-Reggiano is overseen by a consortium. The consortium is responsible for protecting the designation of origin and preserves the cheese’s authenticity and rich history of production by guaranteeing the process followed by the area’s independent producers.

Local cheese-makers prepare the cheese in 40kg wheels that are inspected by the consortium and marked with the inscription “Parmigiano-Reggiano” around the rind. Each wheel is also stamped with the month of preparation, the number identifying the workshop where the cheese was produced, and the consortium’s official seal (pictured at right). Then the deliciously crafted masterpieces are collected for aging.

Local cheese-makers prepare the cheese in 40kg wheels that are inspected by the consortium and marked with the inscription “Parmigiano-Reggiano” around the rind. Each wheel is also stamped with the month of preparation, the number identifying the workshop where the cheese was produced, and the consortium’s official seal (pictured at right). Then the deliciously crafted masterpieces are collected for aging.

How can you tell that the cheese is ready? With a hammer!

When the cheese has aged for over 2 years, experts check each wheel with a small hammer, training their connoisseurs’ ears on the sound and reverberations of the cheese. Our hosts showed us the inside of a wheel of cheese and discussed the different textures and uses for the various parts: cheese on the outside of the wheel is harder and better suited for grated products. Cheese in the middle is higher-quality and better used for cheese wedges like those found in your local grocery, or in my opinion, best used for immediate consumption. One of the many highlights of the visit was the moment when our hosts pulled a wheel down and split it open just for us to taste.

When the cheese has aged for over 2 years, experts check each wheel with a small hammer, training their connoisseurs’ ears on the sound and reverberations of the cheese. Our hosts showed us the inside of a wheel of cheese and discussed the different textures and uses for the various parts: cheese on the outside of the wheel is harder and better suited for grated products. Cheese in the middle is higher-quality and better used for cheese wedges like those found in your local grocery, or in my opinion, best used for immediate consumption. One of the many highlights of the visit was the moment when our hosts pulled a wheel down and split it open just for us to taste.

When the cheese is ready and its quality has been assessed, it enters the packaging facility where it is cleaned, carved, weighed, and packaged. There is very little waste in this facility because the entire wheel can be used. Pieces that are rejected by quality assurance for improper sizing or breakage are sent to the grating room where they can be finely grated into the table parmesan that can be found in virtually every restaurant, and especially pizza parlor, in Italy.

When the cheese is ready and its quality has been assessed, it enters the packaging facility where it is cleaned, carved, weighed, and packaged. There is very little waste in this facility because the entire wheel can be used. Pieces that are rejected by quality assurance for improper sizing or breakage are sent to the grating room where they can be finely grated into the table parmesan that can be found in virtually every restaurant, and especially pizza parlor, in Italy.

We saw multiple packaging lines and various products being prepared from deli-style cheese wedges, to individual snack packs, to grated cheese blends. The most notable part of the factory was the emphasis on quality assurance. Each step of the process was overseen by an employee and double- or triple- checked by computer. In a matter of minutes, a wheel of cheese was sliced, diced, measured, measured again, wrapped, counted, and packaged.

From the director of the facility to the production line workers, you can see the pride for their product in the faces of every Parmigiano-Reggiano employee. They are fiercely proud of their cheese and its authentic origins. “No green bottles here.” Only delicious artisanal creations.

Having had some time to reflect back on the trip I have begun to realize what an amazing experience CHS Inc. provided the students here at Olin. The time we spent in the Parmigiano-Reggiano factory was an experience like no other. Tasting fresh parmesan from a wheel straight from the factory was something I will never forget and I am thankful that CHS Inc. was able to provide us this experience. From marketing to operations the opportunities available for students in the agricultural industry abound and I hope these trips help people learn of the amazing opportunities available in the agricultural sector.

The town is set on a hill with narrow streets, cobblestone roads, and high defensive walls. The most noticeable characteristic about the town are its famous towers which date back to a period when prosperous families sought prestige by building towers to match the height of their status. Currently 14 of the 72 original towers still remain. We were lucky enough to climb the Torre Grossa to catch an exquisite view of the piazza and the rolling hills of Tuscany. Despite the fierce winds at the top of the tower, the essence of beauty and culture this little town exuded is one I will always remember.

The town is set on a hill with narrow streets, cobblestone roads, and high defensive walls. The most noticeable characteristic about the town are its famous towers which date back to a period when prosperous families sought prestige by building towers to match the height of their status. Currently 14 of the 72 original towers still remain. We were lucky enough to climb the Torre Grossa to catch an exquisite view of the piazza and the rolling hills of Tuscany. Despite the fierce winds at the top of the tower, the essence of beauty and culture this little town exuded is one I will always remember.

We were first shown The Villa di Maiano, the impressive main house on the estate, which still had the original décor and furnishings and was the set for the films Tea with Mussolini and A Room with a View. We toured through the house, the exterior garden and terrace. Awed by the views, we saw the working olive farm situated on nearly 300 hectares of land encompassing nearly 20,000 olive trees.

We were first shown The Villa di Maiano, the impressive main house on the estate, which still had the original décor and furnishings and was the set for the films Tea with Mussolini and A Room with a View. We toured through the house, the exterior garden and terrace. Awed by the views, we saw the working olive farm situated on nearly 300 hectares of land encompassing nearly 20,000 olive trees. From the villa, Tomas graciously gave us a tour of the estate mill and described the olive oil production process. I was impressed when he said that the olives are picked entirely by hand and that the estate is completely organic. The olives are typically picked in November and December, and they are processed in the olive mill via a cold extraction process within 6.5 hours of being picked.

From the villa, Tomas graciously gave us a tour of the estate mill and described the olive oil production process. I was impressed when he said that the olives are picked entirely by hand and that the estate is completely organic. The olives are typically picked in November and December, and they are processed in the olive mill via a cold extraction process within 6.5 hours of being picked. When I first learned of the trip, and the support it had received from the CHS Foundation to gain exposure to the agriculture industry, I was excited at the opportunity to learn more about the food products I use in my everyday life. Fattoria de Maiano did not disappoint. It was incredible to see the entire process and to learn exactly how extra virgin olive oil is characterized and the difference from regular virgin olive oil – extra virgin olive oil comes from the first pressing of the olives, contains no more than 0.8% acidity, and is judged to have superior taste.

When I first learned of the trip, and the support it had received from the CHS Foundation to gain exposure to the agriculture industry, I was excited at the opportunity to learn more about the food products I use in my everyday life. Fattoria de Maiano did not disappoint. It was incredible to see the entire process and to learn exactly how extra virgin olive oil is characterized and the difference from regular virgin olive oil – extra virgin olive oil comes from the first pressing of the olives, contains no more than 0.8% acidity, and is judged to have superior taste.

Over the next week, members of the CHS tour will contribute blog posts and photos from their trip. Companies that stand out on the travel itinerary include:

Over the next week, members of the CHS tour will contribute blog posts and photos from their trip. Companies that stand out on the travel itinerary include: